The Best Desulfurization Technology For Power Plant In Coastal Area

Beijing

Longyuan has supplied capacity covering design, manufacturing, erection,

configuring and technical service, meanwhile we also have FGD Technology with completely

independent intellectual property right. Based on 15 years’ seawater FGD

experience, we are able to provide high standard, high environmental-friendly,

high efficiency complete solution of seawater FGD to overseas and domestic

customers in different area with different sulfur concentration. Now we have

taken near 90% domestic seawater FGD market share and near 30% of international

share. As one international advanced environmental protection company who can

provide global service, so far our main customers are located in Chinese

mainland, Southeast Asia and Central Asia.

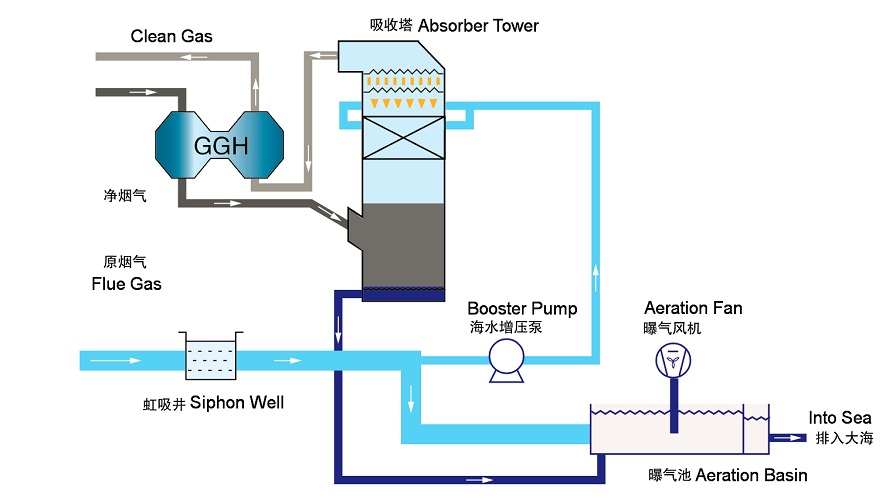

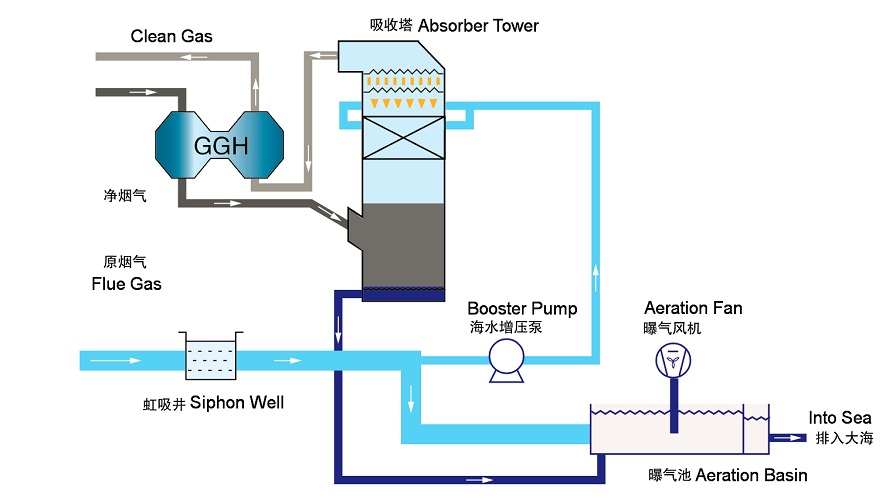

Process Principle

The

seawater FGD process utilizes seawater’ s inherent properties to absorb and

neutralize the sulphur dioxide in the flue gas.

The most important feature of this technology is that it need no other absorbent

without seawater, and will not produce by-product and second pollution, therefore it is totally harmless to ocean and atmospheric environment。At the same time, it has

advantages in many aspects, including simple system, low operation cost, high

removal efficiency (over 95%, even over 99%). Since its standard of discharge

water can meet national seawater quality standard and other related national

water quality standard. It will not make bad effect on surrounding waters, that

makes seawater FGD become the best FGD solution for power plant in coastal

area.

Process Flow Diagram

Using

circulation cooling water of power unit for FGD

The chemical reaction of SO2 in flue gas with seawater:

SO2+H2O→H2 SO3

H2SO3→H++HSO3-

HSO3-→H++SO32-

SO23-+1/2O2→SO42-

The chemical reaction between

hydrogen ion produced above and carbonate in seawater:

CO32-+H+→HCO3-

HCO3-+H+→H2CO3→CO2+H2O

The

seawater that washed flue gas show acid,and has a lot of SO32-(Sulphite ion), so cannot be discharged into

sea directly. The waster discharged from absorber tower will be sent to seawater

treatment plant, after mixed with cooling water from cooling circulation system,will be blow into large quantity of air in order to make SO32- into SO42-and expel CO2 in the seawater. The pH

value and COD index of the treated seawater need to reach the emission standard,

then the threated seawater can be discharged into sea. And the treated flue gas

will be discharged into air through the stack.

Major Features and Strengths

Technology

Mature

technology, simple

process, high removal efficiency, low equipment cost.

Economy

Only use circulation

cooling water as absorbent, no need other additives,which help to save a lot of

cost and no need to prepare limestone’s mining,processing,

transporting and storing.

Environmental

Protection

The process

water treated by FGD system and reach the local coastal area emission standard,

can be discharged into sea. There is no by-product and waste in the process. Thus,

dispose of waste and secondary pollution would be avoided.

Reliability

No scale

and blockage,and

high system utility rate

O&M

lower

operation and maintenance cost compared with limestone-gypsum FGD technology.

Main Performance:

SO2 Removal Efficiency:>95% ;

Plant Power Consumption: 0.5%-1%

System Reliability:≥98%

Aeration Basin

CN

CN

EN

EN