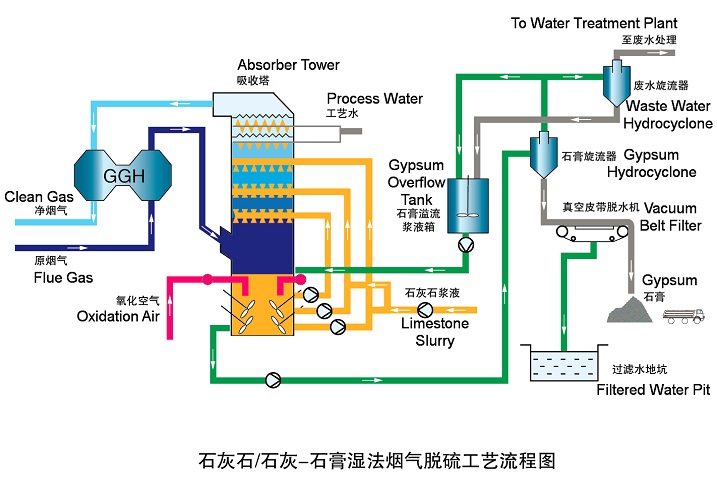

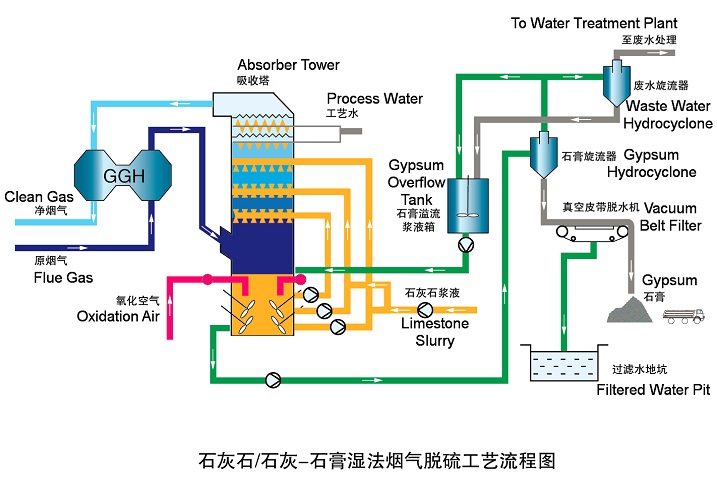

Process Description

The limestone or lime that is inexpensive and easy to get, is used as the desulphurization absorbent of limestone/lime-gypsum wet process FGD technology. The limestone is crashed and pulverized into powder and is made into the absorption slurry after it is mixed with water. When the lime is used as the absorbent, the lime powder will be made into the absorption slurry after it is treated with digestion treatment and mixed with water. The absorption slurry will contact and mix with the flue gas inside the absorption tower. The SO2 in the flue gas will be deprived after it carries out chemical reaction with the calcium carbonate in the slurry and the pumped-in air oxidation. The final outcome of the chemical reaction is gypsum. The desulfurized gypsum slurry will be recovered after it is treated with the dehydration in the dehydrator. In this process, the single-cycle spray empty tower structure is applied. It features mature technologies, wide application scope, high desulphurization efficiency, high reliability and low energy consumption, which is widely used in inland power plants.

Wet Process Features

Absorbent: limestone or lime, cheap price;

Reaction products: gypsum (CASO4'2H20) , can be used for

building material;

Gypsum quality: about 90% purity;

Desulfurization efficiency: more than 95%,SO2< 35mg/Nm3;

The applicability of coal: unlimited, especial for large units;

The calcium/ sulfur ratio: ≤ 1.03;

Water Need to cost fresh water;

Have desulfurization wastewater.

Wet Process Features

Flue gas system: sulfur dioxide absorption system, absorbent preparation system, gypsum processing system, water supply and wastewater treatment system, electrical system, control system; Absorption tower is the core of wet process desulphurization system: is mainly constituted by spray layer (nozzle), mist eliminator, reaction tank, mixing system.

CN

CN

EN

EN